At present, the development of lightweight handheld devices has led to a tight arrangement of internal components, which can cause friction and produce noise when the phone rings or vibrates. In addition, if the speaker design is not reasonable, it can also cause interference in the sound chamber, resulting in increased amplitude, resonance, and noise formation.

The resonance phenomenon of handheld devices not only affects the lifespan of internal components, but continuous vibration can also deteriorate the customer experience and generate noise pollution, posing a threat to the surrounding environment and human health.

In order to solve the resonance phenomenon of handheld devices, Guangmai has developed the DS series products. The DS series products belong to high damping viscoelastic silicone materials, which have both viscosity and elasticity. When the silicone material receives external vibrations or noise, it will generate the movement of polymer chains or segments. Through the intermolecular friction during movement, mechanical energy is dissipated in the form of heat energy, thereby reducing amplitude and achieving the purpose of vibration reduction and noise reduction.

Due to the need for DS products to be used in conjunction with other accessories, Guangmai's R&D department has developed models with different levels of adhesive silicone surfaces based on the differences in usage conditions: DS-H model (high viscosity), DS-M model (medium viscosity), DS-L model (low viscosity). In addition, in response to severe resonance phenomena and ultra-thin space conditions, Guangmai has developed ultra-high damping SHD model products

Product advantages

Multi level viscosity selection

The silicone surface of DS-H model products has high viscosity and is suitable for interface adhesion with low surface energy; The DS-M model has a moderate adhesive force and is suitable for repeated disassembly and installation; The silicone mask of DS-L model has low viscosity and is suitable for use with low adhesion requirements. It can also be disassembled and installed repeatedly. These three models of products can maintain long-term stability in terms of adhesion.

Low silicon volatility

The traditional process involves purchasing raw materials, mixing them directly, and coating them. In order to reduce silicon volatilization, manufacturers will add a secondary vulcanization process before the product rolls leave the factory, which not only reduces production efficiency but also increases costs. The DS series products have controllable raw materials, which can not only reduce silicon volatilization from the source, but also facilitate the regulation of product performance.

Wide effective temperature range

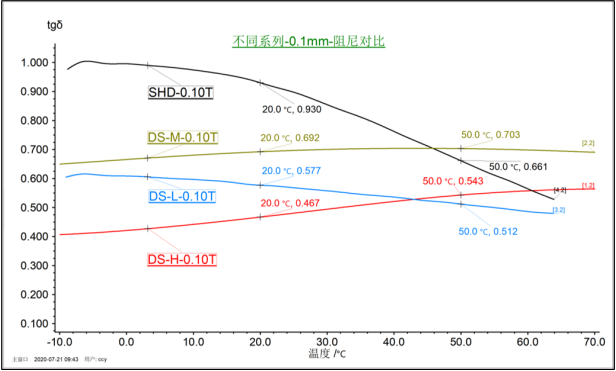

Within the recommended temperature range of -10~70 ℃ for handheld devices, the damping factor of DS series products can reach tan δ>0.4, demonstrating high damping characteristics.

Damping factor variation curves of different models of DS series products

Test conditions: Shear mode, 30Hz

Stable performance

In order to control product quality, Guangmai's R&D department independently designs the molecular chain structure, modulates the raw material formula, and then directly applies it to form. Therefore, the raw materials of the product are controllable, facilitating integrated quality control from raw materials to production, resulting in stable product performance. At the same time, specific products can be developed according to customers' special needs and working conditions.

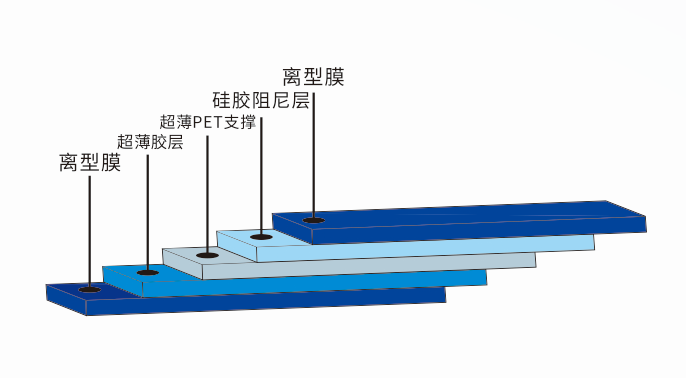

product mix

Product application

The high damping characteristics of DS series products can not only solve the resonance phenomenon of handheld devices, but also be used in other similar scenarios, such as drone shooting shaking, Bluetooth speakers, remote control cars and other machine equipment resonance problems.