Water ripples/white spots are a common problem currently faced by LCD modules. Finger pressure, compression of the back cable, and contact with the housing can all cause short-term water ripples or permanent white spots. The traditional solution is to apply foam to the shell and use foam to relieve pressure or device squeezing. However, it is often difficult to properly isolate the wiring and IC chips.

Our new material PH-RP series products use a micro adhesive surface of foam to directly adhere to the back of the LCD module, which can completely isolate the direct contact between the LCD and other devices, and relieve more effectively. At the same time, micro adhesiveness can ensure that repeated pasting will not tear or affect the backlight film. Our product has excellent thickness retention ability, which can maintain the initial thickness during continuous extrusion, providing consistent performance.

Product features:

Ultra thin thickness, as low as 0.1-0.3mm, provides rich choices for filling ultra-thin spaces

Soft and hard adjustable, different hardness can meet different needs

Micro adhesive surface, can be directly applied to the surface of glass or film without the need for adhesive tape, and can be used in conjunction with graphite sheets

Easy for heavy industry, with strictly controlled surface adhesion, it can ensure the stability of adhesion and meet the needs of repeated adhesion without affecting the backlight film and leaving no residue

Apply without bubbles, using a special formula and process to make the foam have good exhaust function. There are no residual bubbles during the application process, providing convenience for assembly

Good resistance to compression and deformation, providing long-term protection for equipment

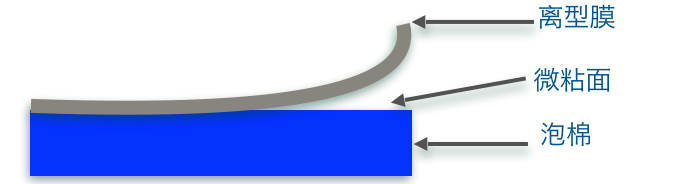

Product Structure:

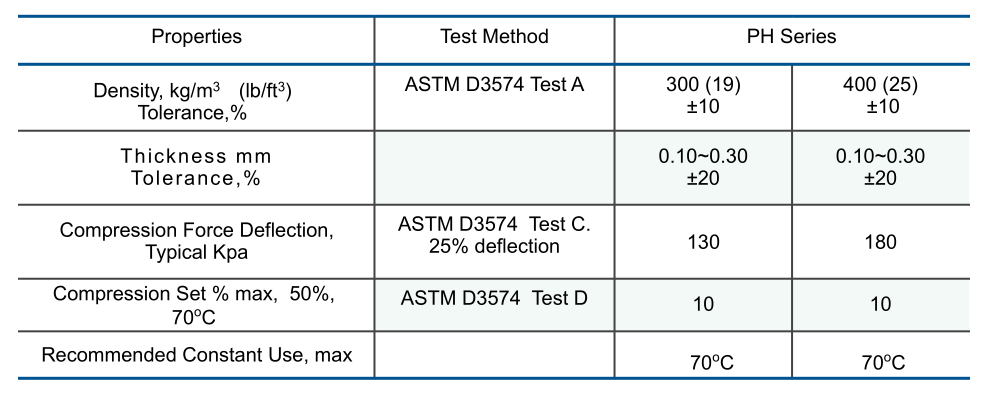

Product performance data:

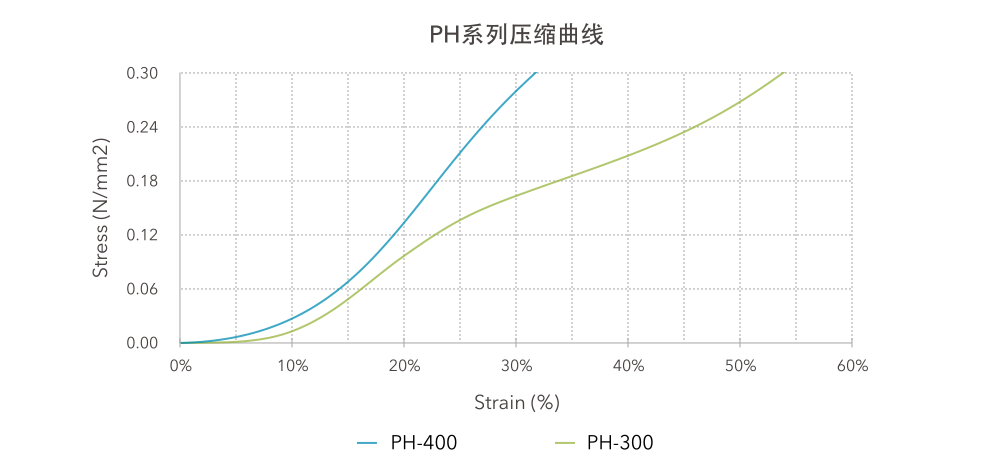

Product compression curve: