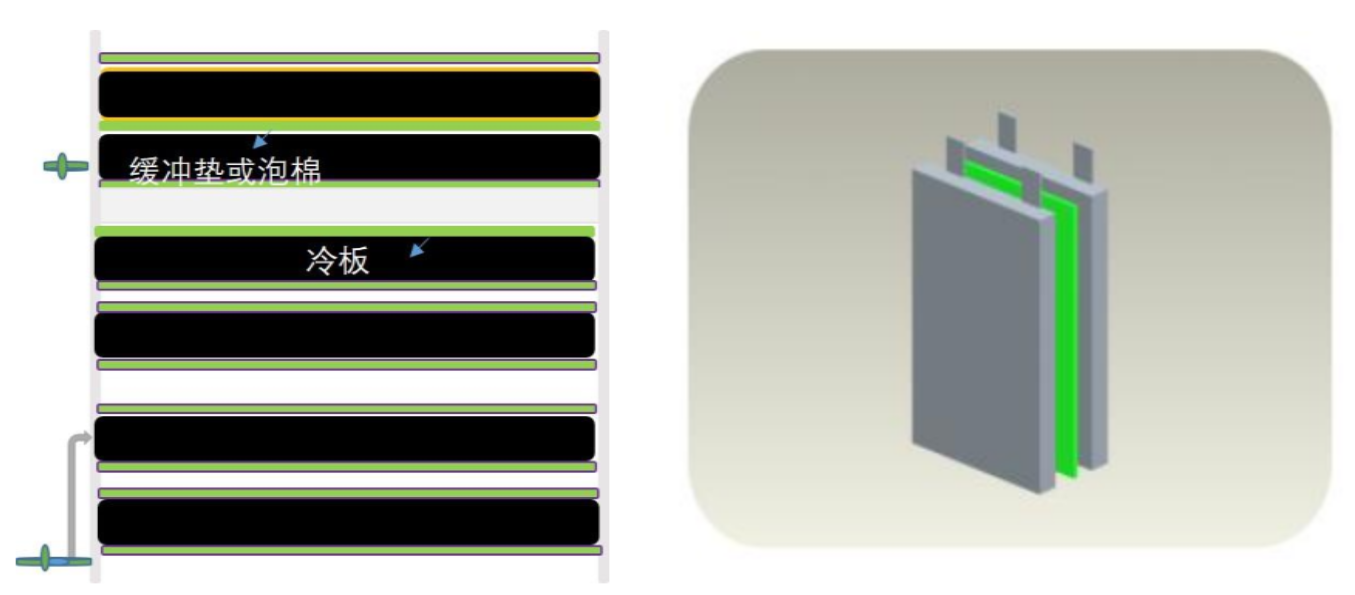

Buffer foam between battery cells

Used for buffering between power battery cells, it can play a buffering role when the cells undergo thermal expansion and contraction; When the battery cell experiences thermal runaway, it can prevent the transfer of heat and has flame retardant properties.

customer demand

Battery cells are the energy source of electric vehicles, and their safety directly affects the overall safety of the vehicle. During operation, battery cells generate a certain amount of heat, which causes thermal expansion and contraction at different temperatures. Prolonged contact friction between battery cells may lead to cell damage, resulting in battery failure or even loss of control. Therefore, based on the application environment of the internal product, a new energy power battery customer has the following performance requirements for buffering products between battery cells:

1. Low hardness and high rebound, able to absorb stress caused by thermal expansion and contraction and provide cushioning effect;

2. Low thermal conductivity plays a role in insulation, suppressing heat diffusion and delaying accidents when thermal runaway occurs;

3. Flame retardant performance, when the battery cell catches fire, the flame retardant effect can delay the spread of fire and increase the time for escape;

4. Excellent rebound performance, with a wide compression ratio for positioning;

5. Small thickness, less space occupation, and long lifespan.

Guangmai Solution

According to the application requirements of customers, Guangmai recommended GK series products with a thickness of 1mm. GK series silicone foam is a super soft silicone foam, which has the characteristics of low hardness, high resilience, excellent temperature resistance, V0 level flame retardant performance, etc. It uses more open hole structures and the persistent resilience of the hole wall to provide a smooth and long-term resilience for the cell, and can contain the expansion and contraction between the cells, meeting the long-term application needs. The thermal conductivity coefficient is 0.08 W/(m · K) at room temperature, making it a good insulation material that can reduce the transfer of heat energy between cells. Its service life is about 10 years, and the thickness selection range is wide: 0.8-12.7mm. A thinner thickness can provide buffering between cells while providing more space for them. At present, the customer has undergone a series of tests and has already started mass production.

Customer needs, our responsibility

Guangmai Electronic Technology Co., Ltd. is a comprehensive enterprise that integrates research and development, production, sales, and service. Provide one-stop solutions for industries such as new energy, railways, and aerospace. Independent research and development capabilities and complete testing equipment enable products to not only have excellent performance, but also provide customized product services for customers. As of now, the company has dozens of patents and has the responsibility and ability to provide customers with high-quality products and thoughtful services.