Ternary lithium batteries have been widely used in the field of new energy electric vehicles due to their high energy density and high discharge power, which is of great significance for maintaining environmental cleanliness and energy conservation. However, soft pack ternary lithium batteries have certain safety hazards. In the needle puncture experiment, it can be seen that at the moment of needle puncture, the battery undergoes drastic temperature changes, with the surface temperature rapidly exceeding 500 ℃ and extreme thermal runaway - violent combustion phenomenon. As a cushioning pad in close contact with soft pack cells, the flame retardancy of the material is also of great significance for improving battery safety.

Needle puncture experiment diagram of soft pack battery

Soft pack cells may swell during charging and discharging, and prolonged friction between soft packs may cause damage to the aluminum-plastic film, resulting in battery failure or even loss of control. Therefore, it is necessary for foam to have low hardness and fast rebound properties, which can absorb the swelling stress of the battery to act as a buffer, prevent relative movement of the battery cells, and provide insulation in the event of thermal runaway of the battery cells, suppress heat diffusion, and delay accidents. When the battery cells catch fire, foam can delay the spread of fire and increase escape time.

Guangmai Battery Buffer Solution

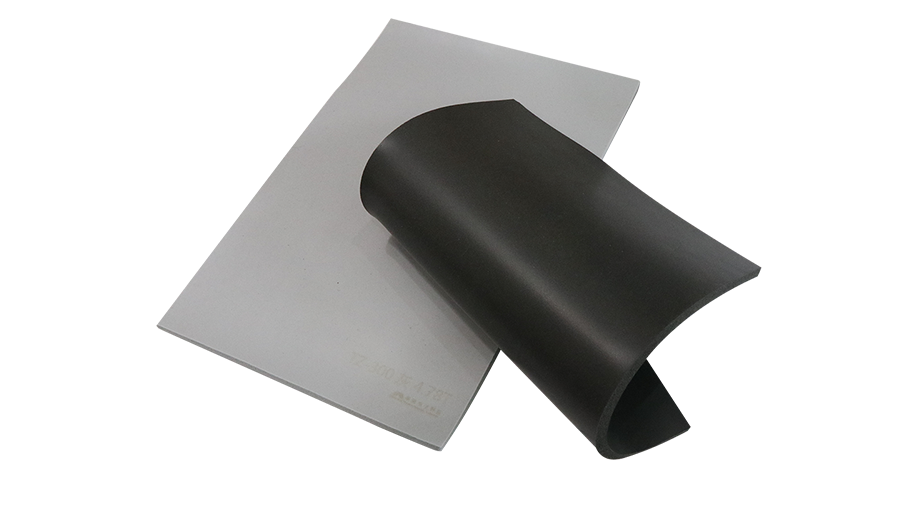

Guangmai has launched MicroES for the application of soft pack battery cells ® GK and GM series silicone foam. The product has excellent flame retardant performance and has passed the EN 45545-2 standard test in the European railway industry. It has reached the HL-3 level in fire retardant and smoke toxicity tests for rail vehicles and meets the UL94-V0 level fire safety standards. It complies with the fire safety regulations of the International Union of Railways and European countries, and can effectively reduce the degree of fire hazard. When a battery cell catches fire, the flame retardant effect of foam can delay the spread of fire, increase escape time, and have the characteristics of low smoke and low toxicity, reducing harm to the human body.

Competitor comparison

Guangmai silicone foam products have a wide temperature range and can be used for a long time from -50 ℃ to 200 ℃. They also have excellent resistance to compression deformation and maintain a constant rebound force. Compared with the 43 series products of an international brand:

Guangmai silicone foam products can achieve ultra-thin thickness (0.5mm), suitable for the application of battery cell cushioning pads. They have the characteristics of low hardness, fast rebound, and flame retardancy, and are continuously optimized to meet customer assembly needs. Traditional silicone foam requires coating with a treatment agent before it can be used for backing during assembly. To address this issue, the GK and GM series can achieve product self adhesion without the need for backing, reducing complex assembly processes and lowering enterprise costs. At the same time, the adhesion between the foam and the battery cell can enhance the positioning of the battery cell and play a certain role in preventing relative movement of the battery cell.