Research

2019-05-14

5309Summary:

At present, foam silicone is a major type of material used for sealing battery pack shells, but foam silicone with different pore structures may have different results when used for sealing: foam silicone with open pore structures cannot be used for waterproof sealing; The mixed pore structure can be used for waterproof sealing, but it cannot meet the requirements for moisture-proof sealing; The waterproof and moisture-proof sealing of closed cell foam silicone can achieve ideal results under ideal conditions. Therefore, preparing a closed cell foam silicone for sealing battery pack shells or other waterproof and moisture-proof seals has a wide range of applications.

keyword:

Battery pack; Moisture proof sealing; Closed cell foam silicone

1. Background introduction

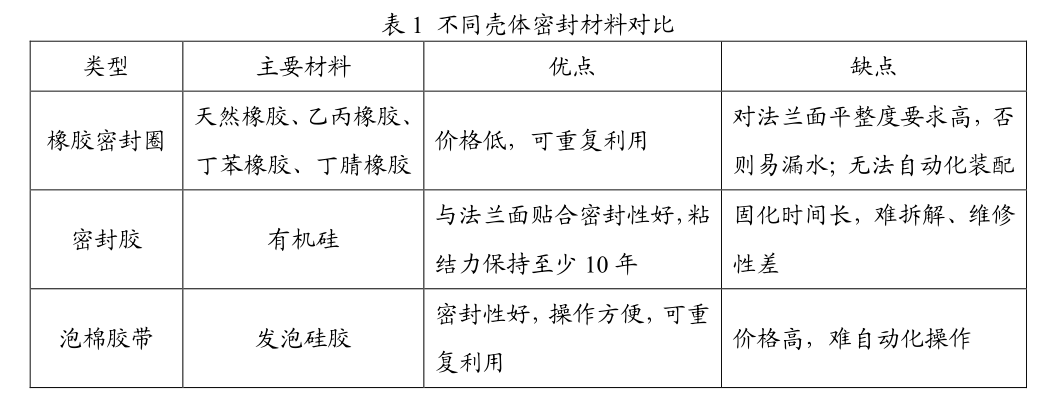

The battery pack is the core energy source of new energy vehicles, providing driving power for the entire vehicle. To protect the internal components of the battery pack from dust, rain, and other erosion, the sealing of the battery pack shell must reach a certain level of dust and water resistance. According to the requirements of IEC 60529-2013 and GB/T 4208-2017 for the protection level of electrical equipment enclosures, the current industry generally requires battery packs to have a protection level of IP67 or IP68 in terms of dust and water resistance. Therefore, the dust-proof and waterproof sealing design of battery packs is very important. There are three main types of sealing materials for battery pack shells on the market: rubber sealing rings, sealants, and foam tapes, each with its own advantages and disadvantages (see Table 1).

At present, there is a strict definition of dust and water resistance levels for battery packs, but there are no relevant standards for preventing moisture. Due to the moisture in the air, it is easy to cause metal corrosion or circuit board short circuits inside the battery pack, and the moisture entering the interior of the battery pack is difficult to discharge. Therefore, it is necessary to consider preventing air convection. Due to the foaming effect of silicone gel itself, air convection may occur in practical applications. Here is a brief introduction to the application of silicone gel in sealing battery pack shells.

2. Application of Foam Silicone in Shell Sealing

Foamed silicone can be divided into open cell structure, mixed cell structure, and closed cell structure according to its pore structure. When used for sealing battery pack shells, foamed silicone is in a compressed state to achieve good sealing effect. The changes produced by different pore structures during compression are different. When these three types of foam silicone with different pore structures are used alone for sealing battery pack shells, they will have the following effects.

2.1 Hole structure

For foam silicone with an open cell structure, due to the interconnected nature of the cells, even with increased compression, it is impossible to completely seal the pathways formed between the cells, thus failing to provide waterproofing. Therefore, in order to achieve waterproofing, foam silicone with perforated structure cannot be used for shell sealing.

2.2 Mixed pore structure

As mentioned earlier, when using foam silicone with mixed pore structure to seal the battery pack shell, the waterproof level of IPX7 or IPX8 can be achieved by compressing and increasing the width of the sealing strip. However, according to feedback from some customers' assembly tests, there may be the following problems in practical applications: after the battery pack works in a humid environment for a period of time, liquid water will appear under the liquid cooling plate.

After testing, it was found that external air entered the interior of the battery pack through capillary tubes formed by bubble holes. The accumulation of water vapor in the air increased the humidity inside the battery pack, and there was a temperature difference of>20 ℃ between the battery module and the liquid cooling plate. These two effects would cause the water vapor inside the battery pack to condense into liquid water below the liquid cooling plate. Over time, the accumulation of liquid water inside the battery pack can affect the performance of the liquid cooling plate and the supporting materials below. If liquid water enters the battery module, it can easily cause a short circuit in the battery cells, affecting the use of the battery pack.

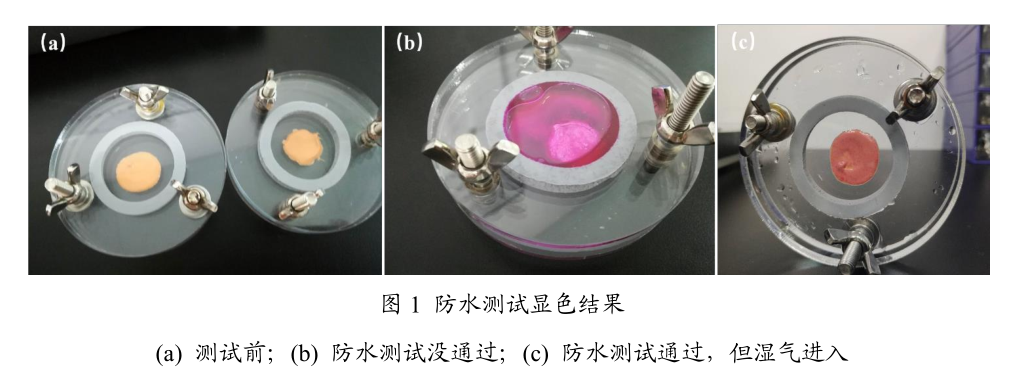

In fact, we also encounter the above phenomenon in waterproof testing. In the laboratory waterproof test of foam silicone, we applied water finding paste (Kolor Kut, USA) to the inside of the silicone ring, compressed the foam silicone with a limit pad, and sank it to the bottom of the water to observe its waterproof effect. Water test paste is a golden brown paste that changes color when exposed to water and deepens with increasing water content. Figure 1 shows the waterproof test of two foam silicone samples. Based on the waterproof test results and the discoloration effect of the test paste in Figures 1 (b) and 1 (c), it can be seen that Figure 1 (b) failed the waterproof test and the test paste turned pink; Although the waterproof test passed in Figure 1 (c), the moisture in the air entered the silicone ring, causing the water test paste to turn brown.

Therefore, in the sealing design of battery pack shells, attention should be paid to preventing air convection and avoiding the entry of moisture, that is, moisture prevention. However, there are currently no relevant standards for the requirements of moisture-proof sealing of shells.

2.3 Closed cell structure

Due to the high mechanical strength of foam silicone with closed cell structure, there may be the following situations when compressed for shell sealing: ① If the compression amount of foam silicone is reduced to maintain the foam cell structure from being crushed, the rebound force of foam silicone acting on the shell will decrease over time due to stress relaxation, which can easily cause interface water leakage; ② If the compression amount of foam silicone is increased in order to increase the rebound force acting on the shell, on the one hand, it will increase the perforation rate and reduce the waterproof performance, and on the other hand, the increase in rebound force can easily cause deformation of the shell.

In an ideal situation, if the elasticity and strength of the foam silicone pore walls are good, and the appropriate compression amount is sufficient to support external pressure without breaking the pores, almost all pores are surrounded by intact pore walls, and no pathways or capillaries can be formed between the pores, fully meeting the requirements for dust, water, and moisture prevention. Japanese patent WO 200722885A1 also mentions the use of ionizing radiation for physical crosslinking, or organic peroxides or sulfides for chemical crosslinking, to manufacture closed cell foam rubber sheets, and to limit the apparent density and compressive permanent strain of the product within a certain range, which can provide excellent waterproof performance. However, there is no introduction to moisture resistance. Patent CN201810372331.6 has obtained closed cell rubber foam that can be used for moisture-proof sealing through the compounding of raw materials and the improvement of processes. Therefore, it is feasible to prepare closed cell foam silicone for waterproof and moisture-proof sealing.

Through the comparison of the effects of different bubble structures mentioned above, it can be seen that closed cell foam silicone has the most promising application prospects in dust, water, and moisture sealing of battery pack shells.

3. Closed cell foam silicone moisture-proof seal

3.1 Differences between dustproof, waterproof, and moisture-proof seals

Dustproof, waterproof, and moisture-proof measures respectively prevent solid (dust), liquid (water), and gas (water vapor) from entering the sealed chamber to avoid adverse effects on internal components or material properties. The difference in fluidity between solids, liquids, and gases is that solids themselves do not have fluidity, and solid molecules can only vibrate slightly in their original positions; Liquids have fluidity, but liquid molecules can only vibrate and translate; The gas has the best fluidity and can flow in any direction.

The difference in the fluidity of these three states of matter determines that the difficulty of dust prevention, waterproofing, and moisture prevention (gas) is gradually increasing. The foam silicone with an open cell structure can achieve the purpose of dust prevention, which is caused by the gravity of the dust itself, air resistance, and the tortuous bubble path; The foam silicone with a mixed pore structure can achieve waterproofing due to the barrier of closed cell walls and the fact that liquids can only flow in parallel; Closed cell foam silicone can prevent water vapor because the sealed pores form multiple layers of anti gas film, preventing gas from passing through and flowing.

3.2 Why can closed cell foam silicone be moisture-proof

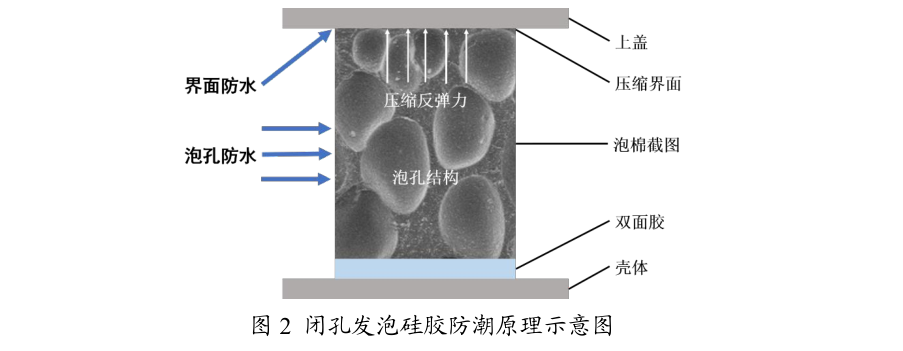

Closed cell foam silicone can achieve moisture resistance when used as a shell seal, as shown in its overall moisture resistance principle diagram 2. The moisture-proof effect of closed cell foam silicone can be divided into two parts: interface moisture-proof and foam moisture-proof.

Firstly, the rebound force generated when the foam silicone is compressed by the shell increases the friction between the foam silicone and the shell, allowing the interface to be fully filled and sealed, achieving the purpose of moisture prevention at the interface; Secondly, the pores of closed cell foam silicone are surrounded by intact pore walls and are not connected to each other. There is no pathway or capillary between the pores, which prevents external moisture from entering and achieves the moisture-proof effect of the pores. The interface moisture-proof and bubble moisture-proof function simultaneously, preventing air convection and playing a moisture-proof role

3.3 Material Performance Design

In the real foam silicone industry, due to issues with raw materials and processes, products with closed cell structures may have high hardness, poor foam wall elasticity, or insufficient flame retardancy. In order to prevent air convection and prevent external moisture from entering the battery pack, and achieve long-term moisture-proof sealing of closed cell foam silicone, the performance of the material must meet the following requirements during production design:

-The closed cell rate of foamed silicone gel is greater than 90%;

-Foam silicone ensures that the pores are not crushed when compressed by 30% or higher

-Foam silicone has good elasticity and low stress relaxation

-Foam silicone has minimal performance loss in environmental testing and a lifespan of over 10 years

-Foam silicone has a flame retardant rating of UL94 V-0

3.4 Airtightness Test

At present, the differential pressure method is commonly used in the testing of foam silicone to test its sealing performance. The principle of this testing method is to measure the pressure change of compressed gas inside the sealing ring after a certain period of time to calculate the gas leakage rate. When the leakage rate exceeds a certain range, it is considered as gas leakage. Due to the short holding time during testing and the fact that the battery pack sealing ring remains compressed during normal use, it is necessary to verify the airtightness of the foam silicone before and after the accelerated aging test and extend the holding time.

4. Conclusion

When closed cell foam silicone is used for sealing battery pack shells, it can prevent air convection and prevent water vapor from entering. At the same time, this material is also widely used in other sealing fields. However, currently closed cell materials have high hardness and are prone to bursting the foam when compressed. Overcoming the shortcomings of the current foam silicone industry and producing a soft and compressible closed cell structure product that can prevent moisture will undoubtedly broaden the application areas of foam silicone and accelerate the development of this industry.

Original submission website; http://www.evpartner.com/news/4/detail-39749.html

Recommend