Popular Science

2019-05-14

10136Fire resistance and flame retardancy are very important in industrial fields such as automobiles, aviation, and railways. Especially in transportation, if a fire is accidentally caught, it will cause extensive combustion and release harmful substances, resulting in casualties and heavy losses. To avoid such risks, using fire-resistant and flame-retardant materials in some key areas is an important guarantee for creating a safe environment. For example, silicone foam used for car body sealing and cushioning needs to meet the strictest UL94 V-0 and HF-1 flame retardant requirements at the industrial level.

The following introduces the flame retardant phenomena in the vertical and horizontal directions according to the testing standards and methods of UL94, as well as the simple laboratory testing methods and standards, which can help us better understand and evaluate the flame retardant and fire resistance performance of materials.

PART ONE UL94 Testing Standards and Methods

Testing instruments

UL94 Horizontal and Vertical Combustion Test Chamber, Bunsen Lamp, Bracket

Vertical testing

testing procedure

1. Sample preparation: Take two sets of 125 ± 5mm × 13.00 ± 0.5mm × Thickness specification samples, with 5 samples in each set (the maximum and minimum thickness of the sample size must be provided, and if the test results are inconsistent, the middle thickness must also be provided, with a maximum thickness not exceeding 13mm).

2. Preprocessing:

① Place in an environment of 23 ± 2 ℃ and 50 ± 10% RH for at least 48 hours;

② Aging at 70 ± 2 ℃ for 168 ± 2 hours, then place in a dryer for at least 4 hours to cool to room temperature.

3. Operation steps

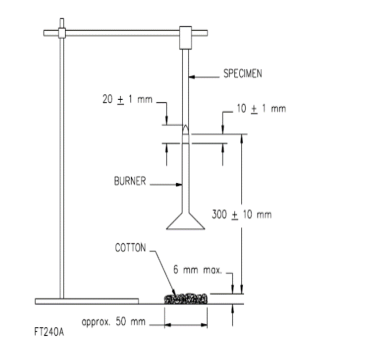

1) As shown in the figure on the right, clamp the sample at the upper 6mm position and place it vertically;

2) By adjusting the intrinsic lamp to a flame height of 20 ± 1mm, the intrinsic lamp is placed at the center of the square below the sample, with the lamp mouth 10 ± 1mm away from the bottom of the sample. A 100% absorbent cotton (50 × 50mm, not exceeding 6mm thick) weighing no more than 0.08g is laid directly below;

3) Ignite for 10 ± 0.5s. After igniting for 10 ± 0.5s, move the burner at a speed of 300mm/s for at least 150mm. At the same time, start recording the residual flame time t1 (if molten or burning substances are dropped from the sample during this period, tilt the burner to a maximum of 45 ° to avoid molten substances dropping into the flame tube). When the residual flame stops, ignite immediately for 10 ± 0.5s. After igniting for 10 ± 0.5s, move the burner at a speed of 300mm/s for at least 150mm, and record the residual flame time t2 and residual burning time t3.

Level Test

testing procedure

1. Sample preparation: Take two sets of 150 ± 5mm × 50 ± 1mm × Thickness specification samples, with 5 samples in each set (the maximum and minimum thickness of the sample size must be provided, and if the test results are inconsistent, the middle thickness value sample must also be provided, with a maximum thickness not exceeding 13mm).

2. Preprocessing:

① Place in an environment of 23 ± 2 ℃ and 50 ± 10% RH for at least 48 hours;

② Aging at 70 ± 2 ℃ for 168 ± 2 hours, then place in a dryer for at least 4 hours to cool to room temperature.

3. Operation steps:

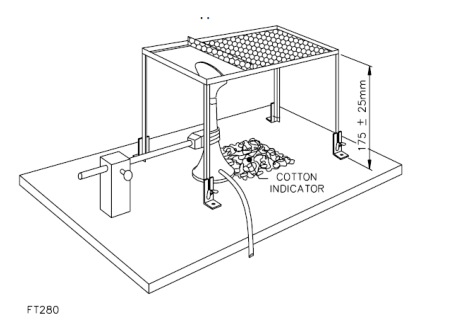

a) Make reference marks at 25mm, 60mm, and 120mm of the sample;

b) Build the device as shown in the figure on the right, with the entire bracket measuring 175 ± 25mm. The distance between the tip of the local lamp and the sample is 13 ± 1mm. Place 50mm x 50mm absorbent cotton with a thickness not exceeding 6mm at the bottom directly below the horizontal plane of the wire mesh;

c) Adjust the flame of the burner to a blue light with a height of 38mm;

d) Apply the external flame of the Bunsen burner to one side of the foam placed horizontally on the wire mesh for 60 seconds, then move the flame away from the sample at a distance of 100mm or more, and start the recording time device. If the flame reaches the 25mm mark, regardless of whether it is at the bottom, top, or edge of the sample, start another timing device to measure the combustion rate of the sample.

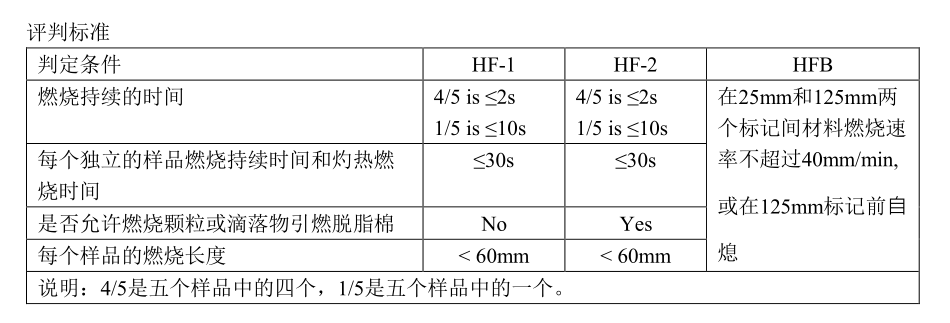

Evaluation method:

UL94 HBF: The material burns no more than 40mm/min between the 25mm and 125mm marks, or self extinguishes before the 125mm mark, but does not meet the requirements of UL94 HF-1 and UL94 HF-2;

UL94 HF-1: At least 4 of the 5 specimens in a group have a burning time of ≤ 2s, and the burning time of any one specimen shall not exceed 10s. After 60mm marking, the sample was not damaged. After the ignition source is removed or marked with 60mm, the specimen burns for no more than 30 seconds without any droplets;

UL94 HF-2: At least 4 of the 5 specimens in a group have a burning time of ≤ 2s, and the burning time of any one specimen shall not exceed 10s. After 60mm marking, the sample was not damaged. After the ignition source is removed or marked with 60mm, the specimen shall burn for no more than 30 seconds, and the molten droplet shall ignite the degreased cotton;